Services

Every part and every customer has specific requirements

Our design department staff and various specialists are well equipped to provide you with innovative, customised solutions to meet your needs in terms of control, logistics or assembly.

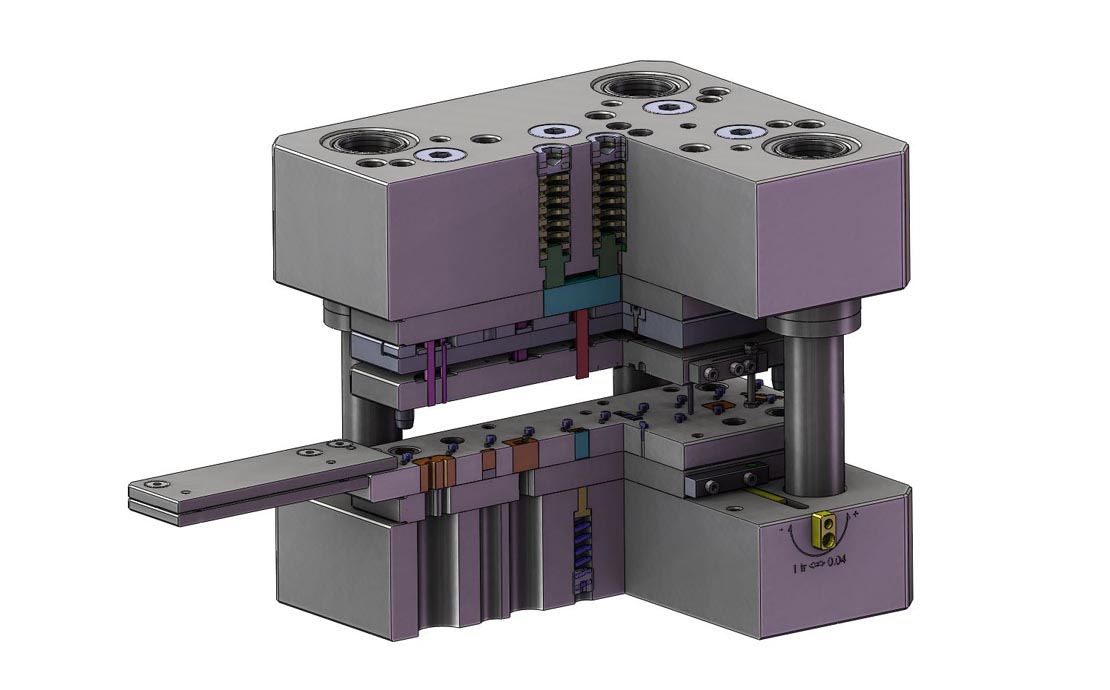

Tool design in SolidWorks.

Unique and specific tool design

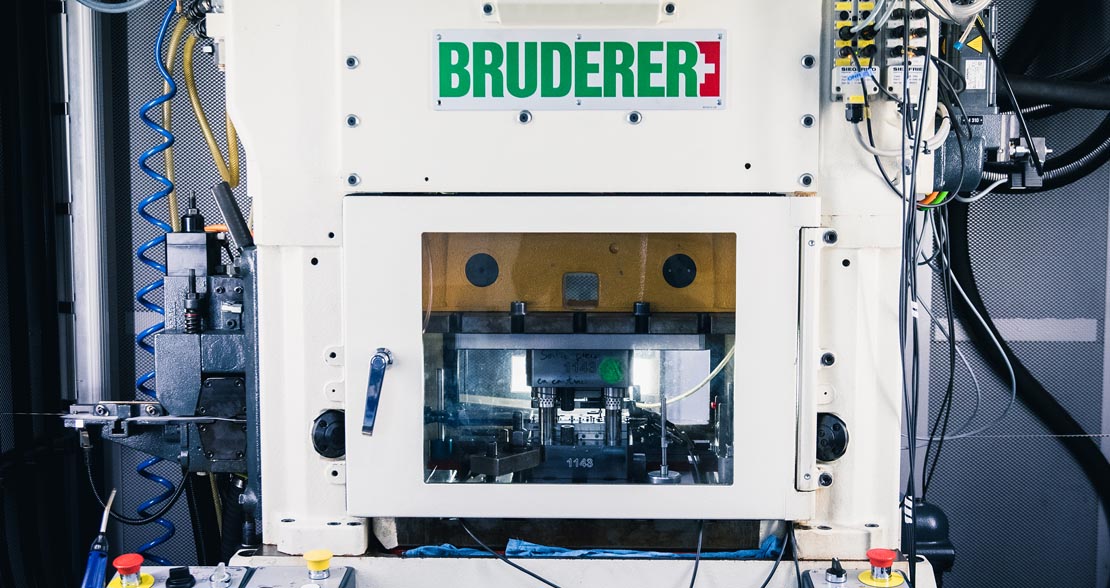

Our stamping dies are produced entirely in-house and the production method that we have developed at MEYLAN Frères SA guarantees you precision, repeatability, productivity and safety for the entire service life of your part. We take care of maintenance, repairs and all production-related parameters.

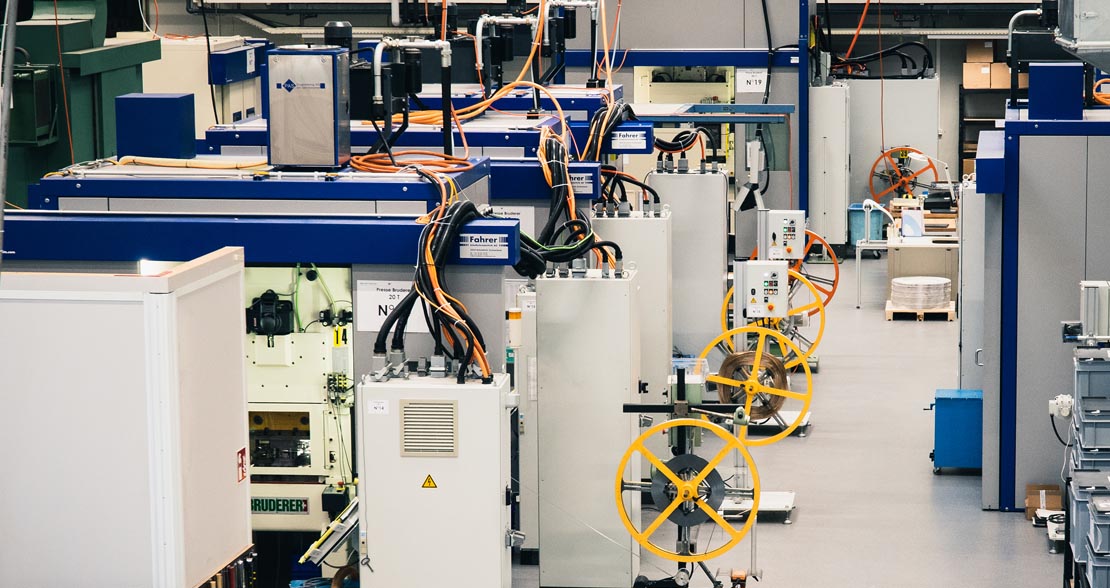

We offer the right solutions all along the production chain

Whether upstream or downstream of the main cutting operations, we offer you the solutions needed to make the entire process safe and reliable. Our know-how and ideas provide you with real added value. This is also a way for us to clearly stand out from the competition.

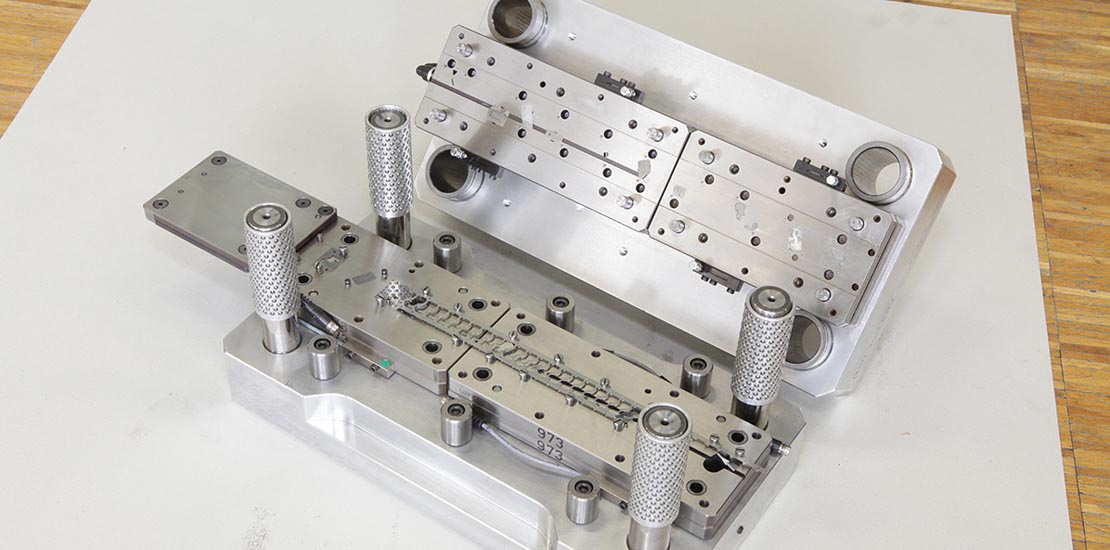

Wire and die-sinking EDM of our tools. Optimal surface quality of strategic tungsten carbide components thanks to machines with an oil bath (AGIE CUT 1000 Oiltech).

Installation, assembly and fine-tuning of our tools by our specialists. Integration of key aspects relating to maintenance and sharpening as well as possible modifications and adaptations.

What is a progressive stamping die?

It is also referred to as a follow-on tool. As the name suggests, it is used to perform multiple operations in succession. With each stroke of the press, the strip advances a step. The part to be produced is achieved step by step.

On this basis, several conclusions can immediately be drawn:

- One of the main challenges of progressive cutting is to guide the strip of material precisely. The aim is to ensure that it is correctly positioned for each operation according to the final part to be achieved.

- A press with a strip feeder that can be adjusted and disengaged according to the position of the press ram is essential.

- The part to be produced must be held in place in the strip until the final operation.

- Before starting production, the setter must “carry out a progression”. The material strip to be cut must successfully pass through all the stages (work positions) of the progressive stamping die. Only a conscientious and adequately trained person is capable of bringing this operation to a successful conclusion.

- Once this progression has been carried out, a part will be produced with each stroke of the press.

English

English  Français

Français  Deutsch

Deutsch