Who are we?

The global service provider for your micro-mechanical parts projects

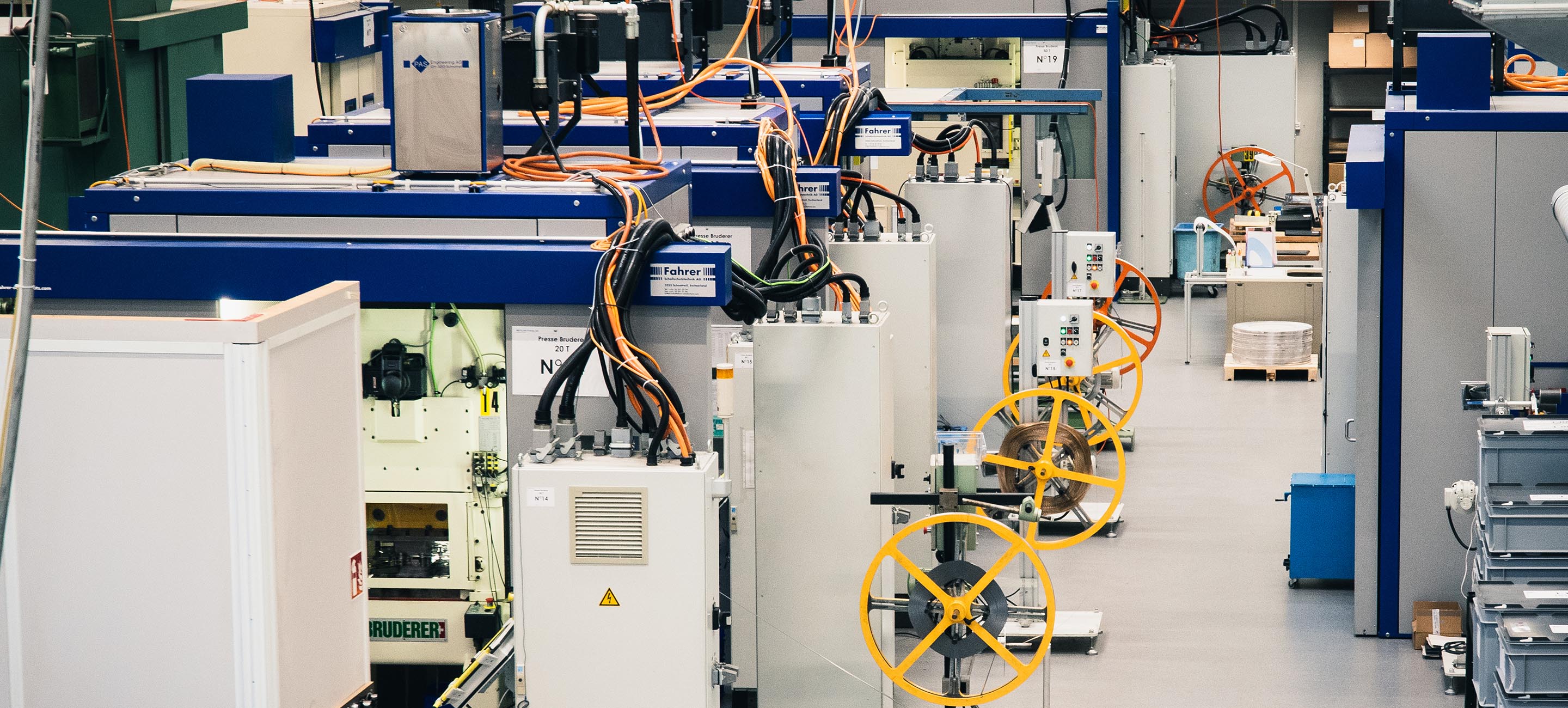

For nearly 50 years, MEYLAN Frères SA has been offering a range of technical solutions for the production of your high-tech micro-mechanical parts from laminated metal (thicknesses from 0.01 to 1.3 mm). Whether you need small, medium or large runs of parts, we constantly invest in our machine park to guarantee you precision and efficiency.

Our services

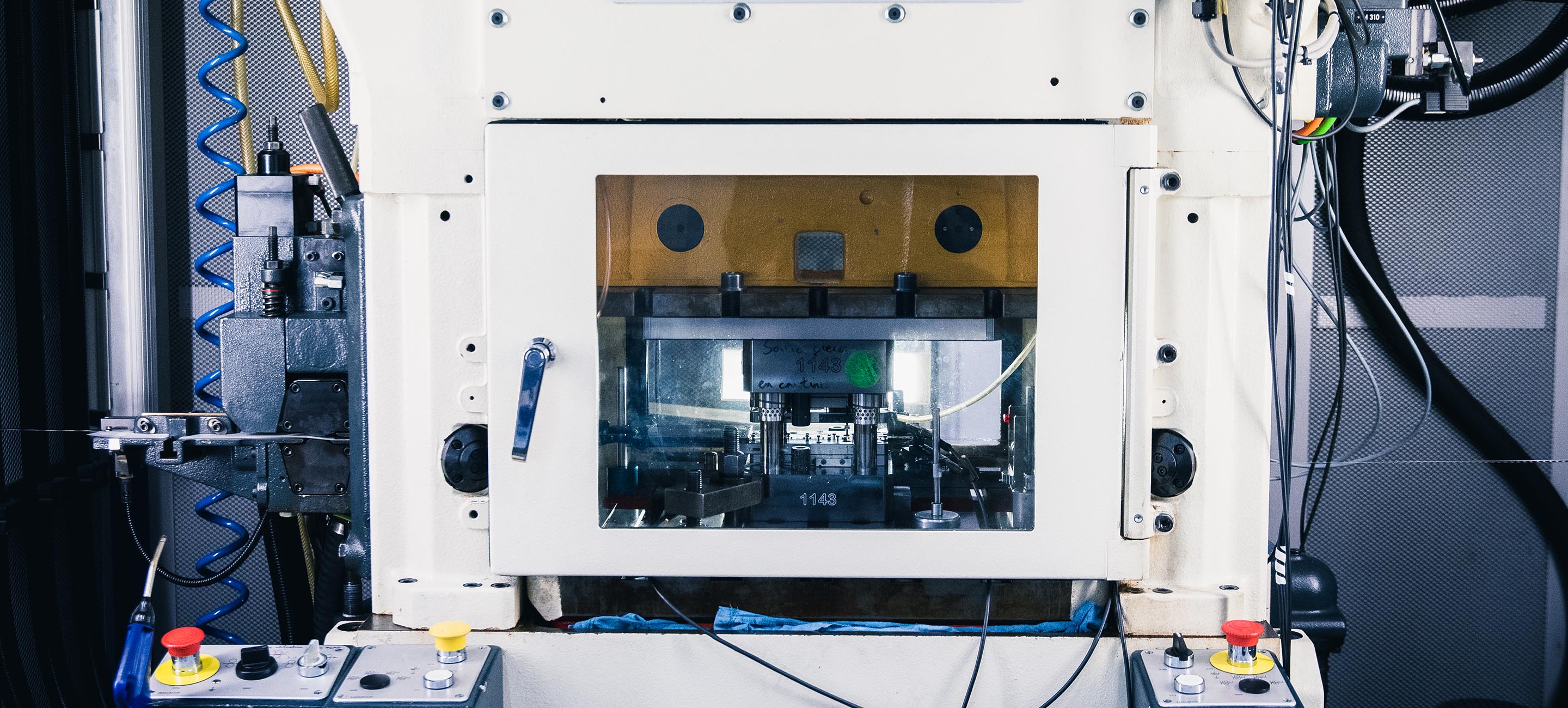

Progressive cutting / stamping

For nearly 50 years, MEYLAN Frères SA has been offering a range of technical solutions for the production of your high-tech micro-mechanical parts from laminated metal (thicknesses from 0.01 to 1.3 mm).

Whether you need small, medium or large runs of parts, we constantly invest in our machine park to guarantee you precision and efficiency.

Electrical discharge machining

We will provide you with innovative, customised solutions to meet your needs in terms of control, logistics or assembly. Our stamping dies are produced entirely in-house. The production method that we have developed at MEYLAN Frères SA guarantees you precision, repeatability, productivity and safety for the entire service life of your part.

At the heart of exceptional micromechanics

We offer the right solutions all along the production chain.

Based on the design of your part, we carry out a study of your progressive tool and its entire manufacturing process and assume full responsibility – from the production to the delivery of your parts, even in very large quantities. Our aim is to supply you with parts in a reliable, productive and economical manner, all based on a relationship of trust and partnership.

Our know-how and ideas provide you with real added value. This is also a way for us to clearly stand out from the competition.

Our internal organisation ensures that the various production processes are highly integrated and complement one another, enabling us to offer you an ideal way to manage quality, costs and deadlines.

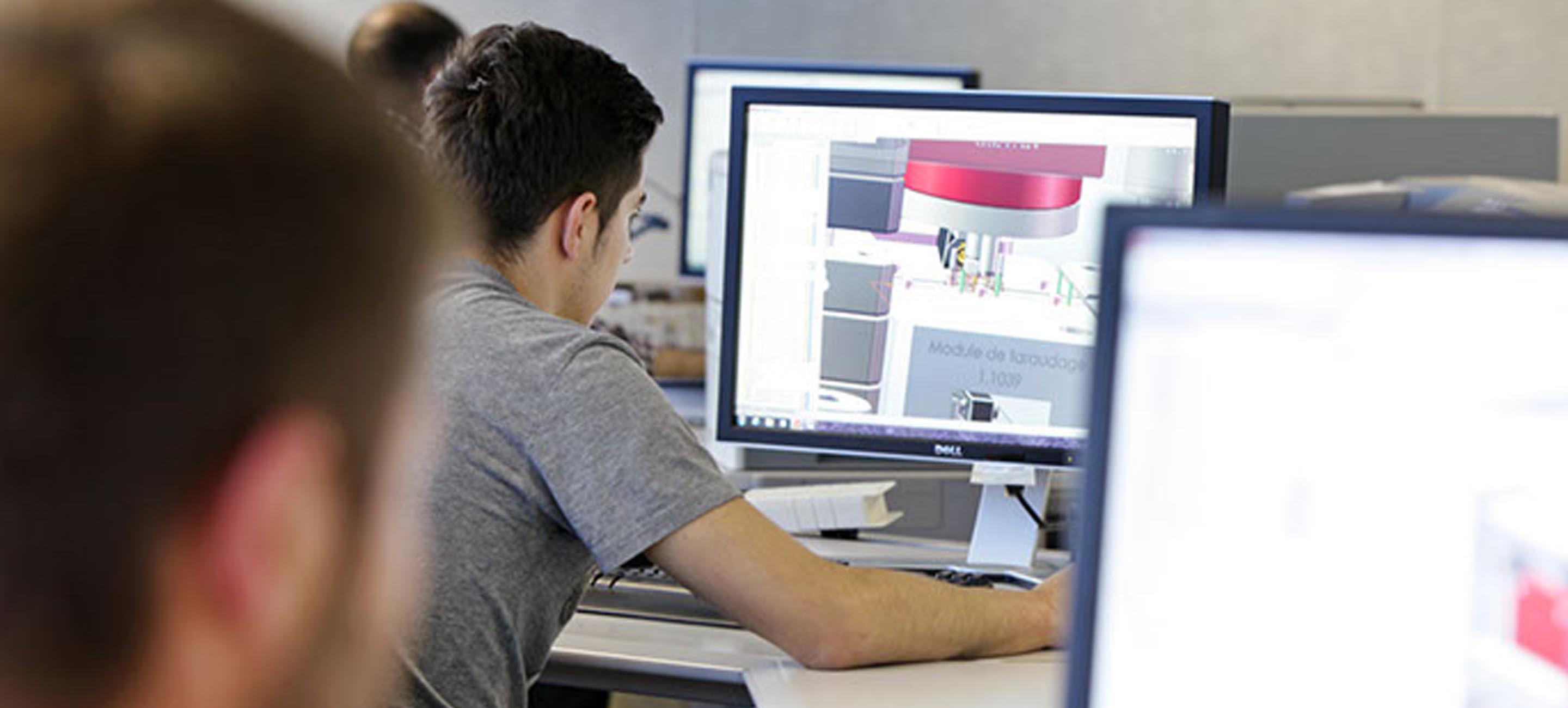

Technical

department

Manufacturing /

machining

Assembly /

maintenance

Production /

stamping

Finishing and

checks

Packing and

packaging

Technical

department

Manufacturing /

machining

Assembly /

maintenance

Production /

stamping

Finishing and

checks

Packing and

packaging

Technical

department

Manufacturing /

machining

Assembly /

maintenance

Production /

stamping

Finishing and

checks

Packing and

packaging

years of know-how

export

qualified employees

quality control

of production

LIFETIME

WARRANTY

MEYLAN Frères SA stamping

Fields of activity

No matter the nature of your project, your needs or your ideas, do not hesitate to contact us.

Automotive

Appliances

Connectors

Watchmaking

Electronics

Medical

English

English  Français

Français  Deutsch

Deutsch